CLEANSKY

PROGRAM

Project made in Cleansky CFP7 europeen research program

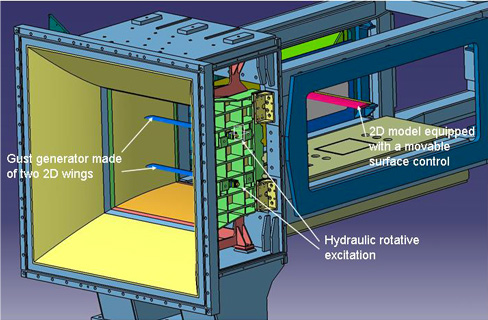

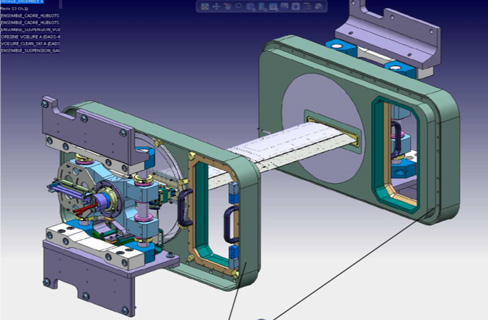

Development and manufacturing of a research test set up

for the investigation of gust loads in wind tunnel.

For transport type aircraft, gust loads are one of the most critical for strength design and fatigue loading source. This project focus on the specific case of gust loads. In this context, R&D activities are foreseen and it is required to have wind tunnel tests on selected technologies to validate the models and analysis that will serve to design the novel control approaches.

To reach these objectives, there was a specific need to dispose of a research tool for the experimental investigation of gust load alleviation on a model demonstrator.

This research tool is composed of

two main components

- The gust load generator to be able to generate calibrated gust perturbations in the wind tunnel;

- A 2D supercritical airfoil wing model equipped with a movable trailing edge control surface and embedded instrumentation for wind tunnel test.

The main objective of the wing model is to study the aeroelastic responses of the model (both structural and aerodynamic responses)

to gust perturbations produced by the 2 gust generators.

The experiments were carried out at ONERA’s Meudon Center’s S3Ch research wind tunnel (transonic continuous wind tunnel).

The gust generators and wing model have been CAD designed and made in carbon with metallic structure in our factory.

A complete hydraulic activating system was supplied.

The complete system was tested in the ONERA Meudon S3 Ch research wind tunnel.